We've got answers

So you'd like to build something special. Maybe it's a modest home, or barn for your car collection, or a whiskey distillery with tasting room. It's something you want to enjoy but not break the bank to have.

Here are some of the common questions we get and the answers to them.

- Beauty and Strength. Nothing else has the beautiful warmth and strength of wood timbers.

- Timber frames go up fast. A typical timber frame can be completed in as little as 5 days.

- Timber frames can be used with conventional stick construction. For example: we've had many clients ask for a "great hall" in their new homes while the rest is built with stud construction.

- Timber frames and SIPs are a marriage made in heaven. They will shorten your build cycle, save you money, and give you a home you'll be eager to welcome friends and family into.

Your crew exceeded ABOVE AND BEYOND my biggest expectations. ... Having worked through a Nor'easter and then to have a blizzard blow through and knock the power out of the town while dealing with the cold weather, it was unbelievable to see how much work was being done each day!Christie - Blue Hill, ME

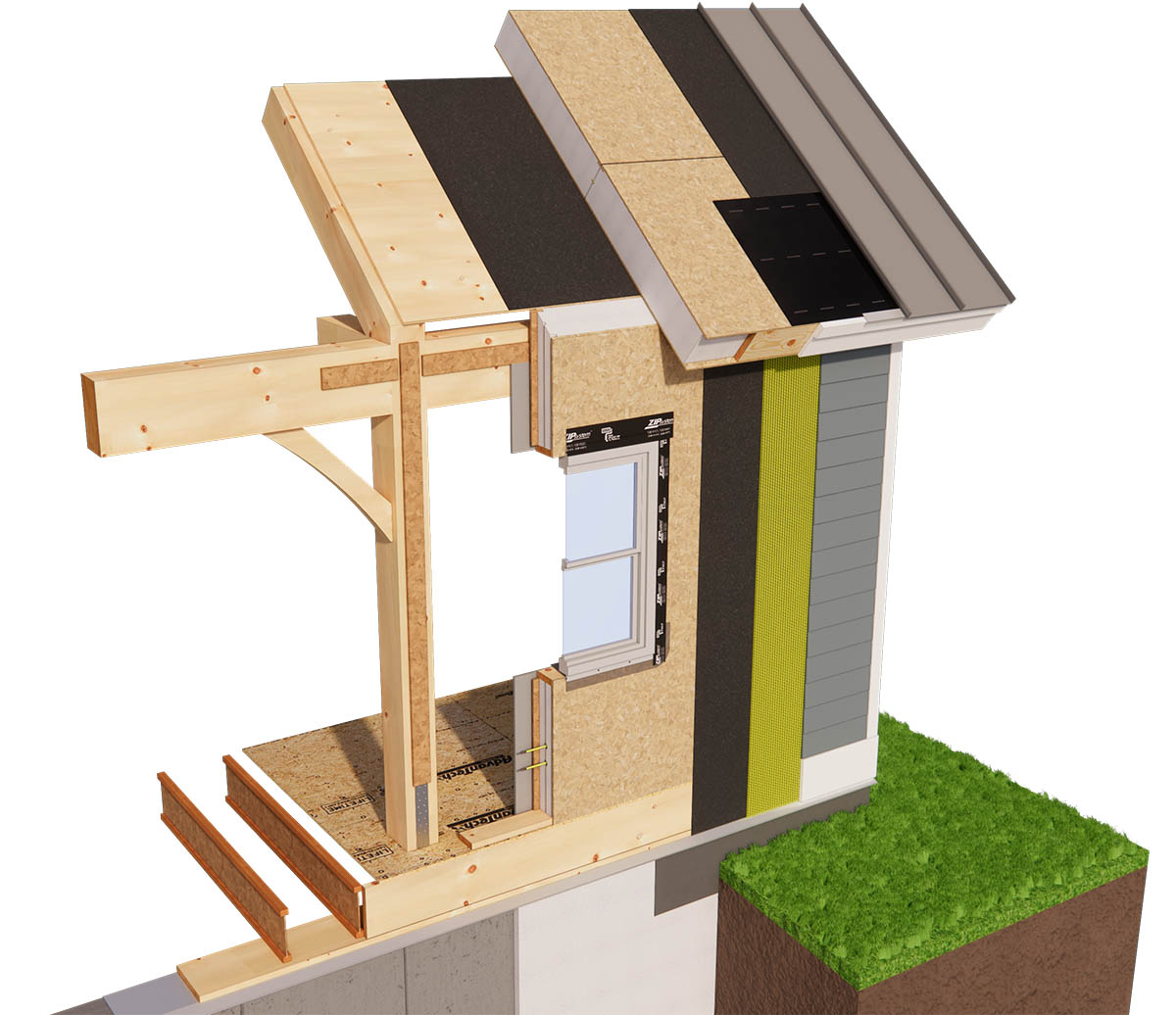

SIPs (Structural Insulated Panels) are rigid insulation sandwiched between two sheets of oriented strand board (OSB). Our SIPs come with an EPS or GPS core. GPS has a higher R value.

- SIPs have higher R values per inch thickness than cellulose or fiberglass insulation.

- SIPs go up fast. A typical install can be completed in 2-5 days.

- SIPs are strong. A 6” thick SIP can carry the same load as a 2” x 10” framed wall. In fact, you can build small homes with just SIPs for the exterior walls and roof.

- SIPs are light. An 8’ x 12’ panel can be easily carried by two people.

- SIPs are energy efficient. SIPs provide a continuous thermal envelope with almost no thermal bridging.

- SIPs don't use studs, hang your cabinets or pictures where ever you like.

- SIPs don't smell. There's no off-gassing.

- Our SIPs are made with your choice of Expanded Polystyrene (EPS) or Graphite Polystyrene (GPS). They contain no chlorofluorocarbons (CFCs), no hydrochlorofluorocarbons (HCFCs), and no volatile organic compounds (VOCs).

- We design our panel installations to minimize waste in production and on the job site.

- The gas used in the production of the foam panels (pentane) occurs naturally in our environment.

- The wood used for the OSB panels comes from young trees grown on tree farms - a renewable resource.

- While SIPs have a relatively low Embodied Carbon footprint (all emissions related to the construction processes of a building, through its whole life cycle), they have a very low Operational Carbon footprint (emissions released from the ongoing energy usage that operates a building compared to other types of wall construction).

- When you consider energy efficiency, carbon footprint, longevity, strength, and energy savings over time, there's no better way to wrap your home.

Timber frames are an upgrade to conventional framing.

SIPs are an upgrade to conventional framing and energy efficiency.

They may cost a bit more but when combined, that gap is significantly reduced. How much more? That depends on many different factors. Here are several things to consider:

It is below zero today. Our propane fireplace was on this morning at 7:30 and will not come on again until 8:00 or later this evening. Our home is so well insulated with the stress panels [SIPs] that we truly expect a heating bill of less than $10 per month when it is -10 outside!Harry and Glenda - Jefferson, CO

Patrick Hudson ~ Hudson Design and BuildAt Hudson Design and Build, we’ve partnered with Vermont Frames on several timber frame homes, and the experience has been exceptional every time.

From the start, their design process is easy and collaborative—working seamlessly with us and our clients as one team…Vermont Frames isn’t just a supplier—they’re a trusted partner in delivering beautiful, lasting homes.

We design, build, and install timber frames and SIPs for projects from great halls and pergolas to large commercial spaces. That's all we do because they're the perfect match.

Our designers and workshops are on the same site so if we need to answer a question or address an issue, there's little to no delay.

Our SIPs are manufactured to your specifications with panel sizes up to 8' x 24'. We’ll precut the bevels, wire chases, and window & door rough openings, which saves you weeks of time and avoids messes on your site..

We're proud to carry on the tradition of timber framing by hand cutting every timber. We believe the craft of timber framing is important and should be kept alive.

Our SIPs are certified strong. See the Uniform Evaluation Service (UES) Code Report.

Our crews have received high praise from many clients over the years for their craftsmanship, professionalism, and speed. The finished products speak for themselves.

If you have any questions, give us a call at 802-453-3727.